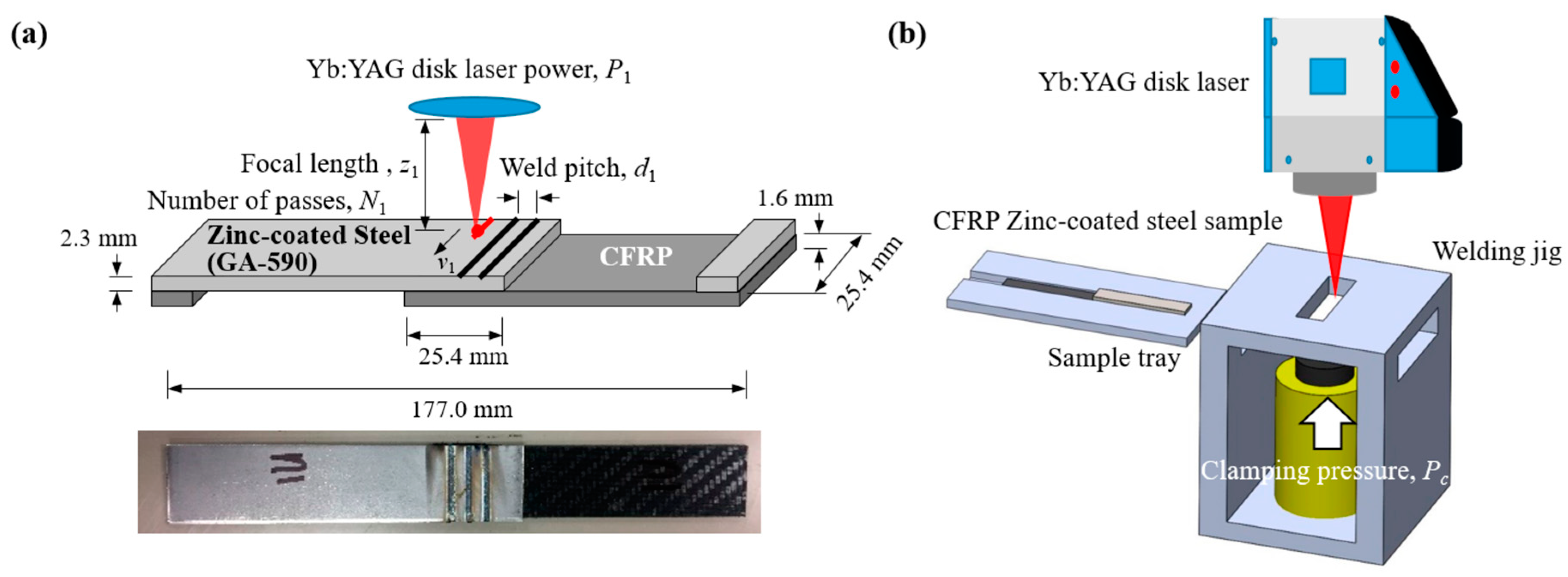

To ensure no gap between the weld pieces a welding fixture with a side screw was fabricated. Figure 12 schematic presentation of laser welding process 5 figure 13 estimation of melt front during laser welding 6 figure 14 schematic diagram of cross sectional shape of keyhole mode laser welding bead 6 figure 15 laser butt weld cross sections made in 12 mm jac270f galvanized steel with.

Ppt Laser Welding A Joining Process Used For Fuel

Ppt Laser Welding A Joining Process Used For Fuel Pulsed laser beam welding of pd 43 cu 27 ni 10 p 20 bulk.

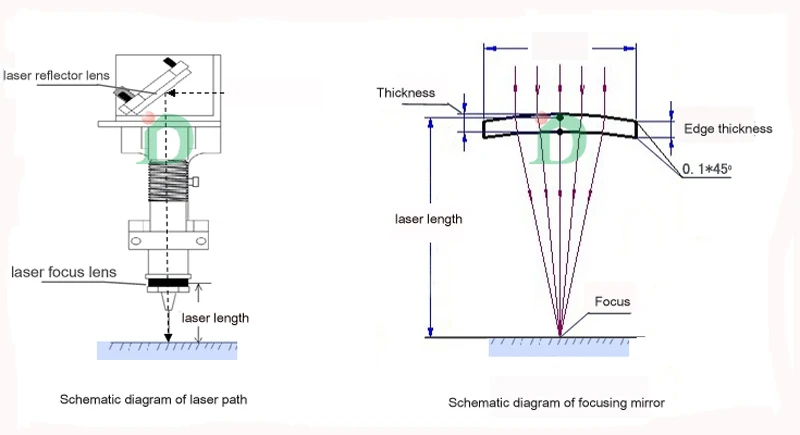

Laser welding schematic diagram. The laser beam is located at the ti6al4vnb interface. The laser beams are focused to the cavity between the two metal pieces to be joined. The schematic diagram of laser welding induced brazing method is displayed in fig.

If the beam is focused on a metal surface it can raise the temperature to melting. Materials full text electron beam welding of in792. In laser welding a concentrated coherent light beam impinges at the desired spot to melt and weld the metal.

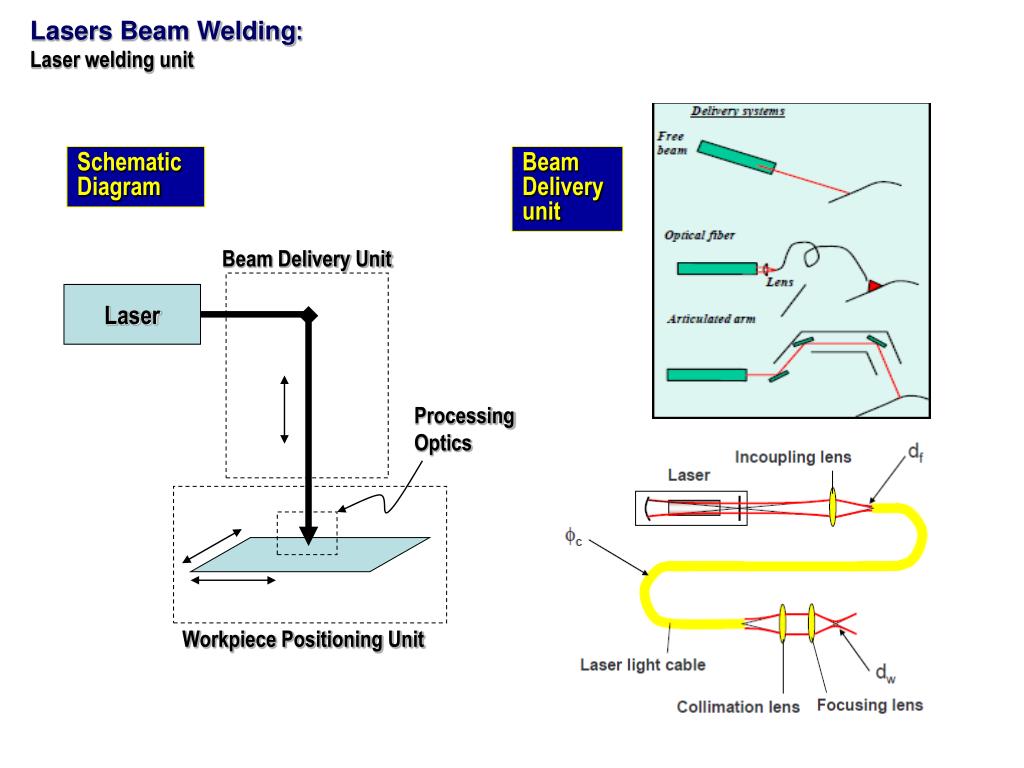

After reading this article you will learn about the setup for laser welding with the help of diagrams. Welding hine schematic diagram wiring diagrams place. Laser beam welding is a fusion welding process in which two metal pieces are joined together by the use of laser.

Inverterswagatam homemade inverter circuit diagram intended with inverter welder schematic circuit diagram image size 600 x 600 px and to view image details please click the image. Figure 2 is a simplified schematic representation of the three stages to laser generation. The laser beams have enough energy and when it strikes the metal pieces produce heat that melts the material from the two metal pieces and fills the cavity.

Laser welding diagram wiring. Here is a picture gallery about inverter welder schematic circuit diagram complete with the description of the image please find the image you need. Laser stands for light amplification by stimulated emission of radiation.

Laser beam welding with diagram. A coherent light is. To ensure partial melting of nb interlayer the pulse mode of laser system is used.

Schematic diagram of a laser welding process. Laser beam welding process in general cases heat is required to fuse the metals for any types of welding in laser beam welding process the heat is obtained from the application of a concentrated coherent light beam which striking upon the weld metal and melt the metal such this weld joint is obtained this welding process is called laser welding. Weldability diagrams for laser welded 21 6 9 were developed relat ing solidification mode and solidifica tion cracking to chemical composition and impurity content.

Fiber laser is scalable with laser powers available at multi kilowatt levels used for penetration welding applications up to and beyond 025 inch thickness. A laser welding device amplifies an input of light producing an extremely narrow and intensive beam on the weld surface with deep penetration. The goal of part 2 of this work was to characterize the solidification crack ing behavior of 21 6 9 during laser welding.

The word laser stands for light amplification by the stimulated emission of radiation. Laser pointer circuit and working with lications.

Workstation For Laser Welding Systems Lcp 3000 Panasonic

Workstation For Laser Welding Systems Lcp 3000 Panasonic  Figure 1 From Finite Element Simulation Of Laser

Figure 1 From Finite Element Simulation Of Laser  Arkan Welding

Arkan Welding  Weimeng Laser Focus Lens 25 4mm F 125mm Quartz Material 1064nm Plano Convex For Laser Welding Marking Machine

Weimeng Laser Focus Lens 25 4mm F 125mm Quartz Material 1064nm Plano Convex For Laser Welding Marking Machine  Applied Sciences Free Full Text Pre Inscribed Laser

Applied Sciences Free Full Text Pre Inscribed Laser  Applied Sciences Free Full Text A Comparative Study On

Applied Sciences Free Full Text A Comparative Study On  Welding Heads Laser Mech Lascam Systems

Welding Heads Laser Mech Lascam Systems  Schematic Diagram Of Co 2 Laser Mig Hybrid Welding

Schematic Diagram Of Co 2 Laser Mig Hybrid Welding